It is no surprise that the world of energy is preparing for a massive transition these days, and the necessity to create cleaner energy generation through a low carbon development has becoming more apparent than ever. Since the COP26 held in Glasgow last year, the movement of countries to disseminate green technologies are massively encouraged to comply with global emission targets mentioned in the National Determined Contribution (NDC). There have been many agreements with the term of “Glasgow Breakthroughs” with the aim on increasing green technology implementation so that it will be more affordable, accessible, and attractive for many energy users.

However, before reaching into that equilibrium, there will be a time where the technology price would rise and burden the cost of production—just like how it has happened with solar PV technology—due to new technology adoption. Unfortunately, this transition is inevitable, and all industrial players will have to follow this trend. For example, PT Coca-Cola Europacific in West Java and PT Danone Aqua in Central Java are among the two biggest early adopter of clean energy generation in their manufacturing plant. It is very likely that other manufacturers will follow this trend in the imminent future.

To obtain better understanding of manufacturing segment in Indonesia, first let’s take a look at Graph 1.

It can be seen that Industrial Sector takes up the second place in consuming national energy with 36,5% share after Transportation Sector with that of 44%, and among those shares, Industrial Manufacturing Sector has the majority contribution to this energy consumption compared to other sector such as Mining and Construction. Moreover, the Industrial Manufacturing Sector is divided into two groups where they are called HEIMI (High Energy Intensity Manufacturing Industry) and LEIMI (Low Energy Intensity Manufacturing Industry).

It can be seen that Industrial Sector takes up the second place in consuming national energy with 36,5% share after Transportation Sector with that of 44%, and among those shares, Industrial Manufacturing Sector has the majority contribution to this energy consumption compared to other sector such as Mining and Construction. Moreover, the Industrial Manufacturing Sector is divided into two groups where they are called HEIMI (High Energy Intensity Manufacturing Industry) and LEIMI (Low Energy Intensity Manufacturing Industry).

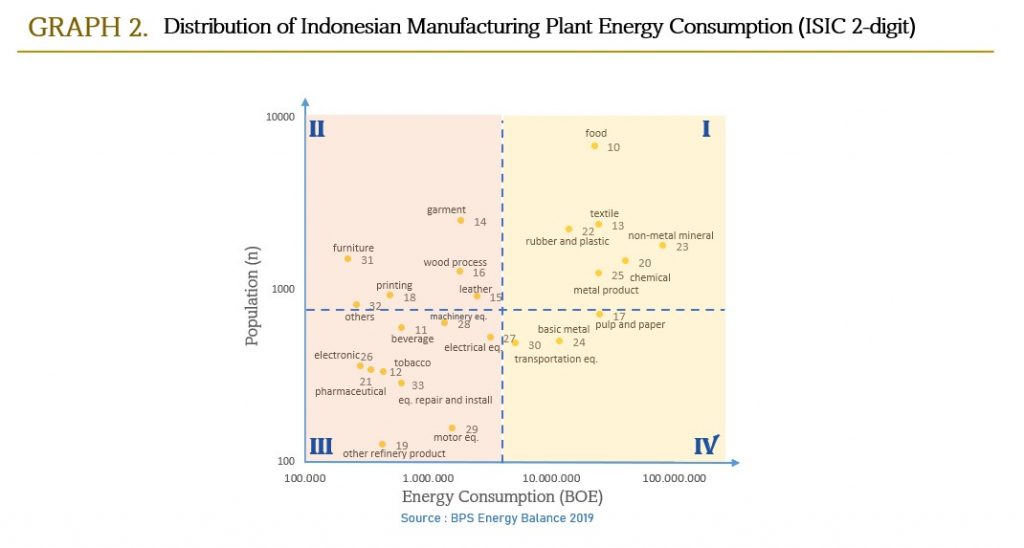

PetroRaya believe that targeting HEIMI industries will give significant impact into national energy intensity level, and it will be more effective instead of targeting LEIMI. Next, as the energy intensity is getting better, all types of energy will surely be utilized more efficiently and eventually decrease the emission level as well. In the Graph 2, we try to map the Manufacturing Industries in Indonesia in ISIC 2-digit classification (International Standard Industrial Classification) based on their number of plant population and energy consumption.

Using this simple matrix, the manufacturing sectors are divided into four quadrants, where horizontally the energy consumption is getting bigger and vice versa, also vertically the number of plant population is getting larger and vice versa. Basically, the typical characteristic of the industries will be as follows:

Q-I : Large number of populations with High energy consumption

Q-II : Large number of populations with Low energy consumption

Q-III : Small number of populations with Low energy consumption

Q-IV : Small number of populations with High energy consumption

For example, Food (10) and Pulp-Paper (17) has similar energy consumption level with different number of populations, meaning that the average energy consumption of Food should be less than Pulp-Paper. While Pulp-Paper (17) has similar number of populations with Machinery Equipment (28), their energy consumptions are very much different, meaning that Machinery Equipment must have lower average energy consumption compared to Pulp-Paper. In this example alone, one could draw a conclusion that it will be more impactful to apply green technologies in Pulp/Paper and Food compared to Machinery Equipment judging from their energy consumption only.

Furthermore, it is known that there are many parameters affecting energy price, such as energy utilization (how the energy is being used within the plant), energy efficiency (how efficient the equipment is used) and energy consumption (the amount of energy consumed within the plant), and among these three parameters, energy consumption is arguably to be the most impactful of them all. By this approach, when energy cost is associated with energy consumption than any effort in optimizing energy utilization should reduce energy cost in the long run, including implementing green technologies to improve the energy intensity within the manufacturing sector.

In the end, it is necessary to have further analysis on how the energy is utilized within the manufacturing plant, how is the condition of the equipment used and what can be done to achieve a cleaner production. But for a starter, one could see that this is a concrete approach that is feasible for the industrial manufacture players within the country.

Source :

Handbook of Energy & Economic Statistics of Indonesia (Ministry of Energy and Mineral Resources Republic of Indonesia)

Manufacturing Industrial Statistics (Statistics Indonesia)

Energy Balances of Indonesia (Statistics Indonesia)